- 2018- Manage and Review on Behalf of Canadian National Rail client’s Analysis of the Computer Aided Dispatching System Functional Hazard Analysis (FHA) / Operation & Safety Hazard Analysis (O&SHA) developed by General Electric for Rail Movement Control and Dispatching.

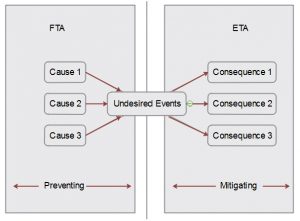

- 2018- Manage and Review on Behalf of Canadian National Rail client’s Analysis FHA, FTA, FMECA, O&SHA of the Back-Office System (BOS) Positive Train Control developed by SIEMENS.

2018: Review on Behalf of the Client BOMBARDIER the FMECA of Subway Cabs control System. - 2018: Development by our experts a Cybersecurity protocol for communication system (SinCRY)

2017 Perform the Fire Safe Shutdown Analysis (FSSA) Point Lepreau power plant. - 2017: Development of RAMS SCADA and DCS systems/subsystems for the Kirkuk Crude Oil Pipeline control stations;

2017: Development of Safety and Risk analysis of the Chalk-River waste treatment center Facility using Techniques HAZOP/HAZID to produce the list of Hazards and their Mitigation Controls. - 2013-2017: Perform PHA/HAZOP/HAZID and Reliability-Availability-Maintainability and Safety (RAMS) to identify hazards and risk mitigation strategies for Design Modifications of Industrial and nuclear facilities for the Canadian Nuclear Laboratories (Waste treatment Center, U-2 fuel test facility, Molybdenum Production Facility, Nuclear Fuel Fabrication Facility, R&D facilities, Isotopes production Nuclear reactor NRU, ZED-2 testing research reactor, etc..).

- 2013: Perform Technical-Economic study & Design of WTE plant within Kenitra-Morocco city for the treatment and valorization of 1000 MT per day of MSW and waste water treatment sludge. This study has been carried out in the context of a BOT contract to evaluate the economic benefit to implement WTE units in Kenitra city to produce electricity through pyrolysis-gasification technology and fertilizer for the organic components.

- 2013: Risk evaluation using HAZID, HAZOP and QRA of the Phosphoric acid processing plant on behalf of the Tunisian Chemical Group, Tunisia.

- 2013: Perform to Tunisian Chemical Group a strategic plan for the valorization of Phosphoric Acid By extraction of raw material such as Uranium and Rare Earths.

- 2012: Perform Technical-Economic study & Design to implement WTE plant within Almaty and Astana (Kazakhstan) cities for the treatment and valorization of 2000 MT per day of MSW. This study has been carried out for the 2 major cities in Kazakhstan Almaty and Astana o evaluate the economic benefit to implement WTE units to produce electricity through pyrolysis-gasification technology and fertilizer for the organic components.

- 2011: Develop and Lead Training Lecture to Colombian TRIGA research reactor staff on behalf of the IAEA on topics safety and risk requirements for research reactors and the use of the IAEA standard documents. This Training lecture is meant to enhance the capabilities on the safety and risk assessment methodology and requirements, mainly deterministic and probabilistic, for the staff to be involved to restart the operation of the Colombian TRIGA research reactor.

- 2011: Develop and Lead Training Lecture on behalf of the IAEA Tunisian fellowship to enhance their capabilities for the Tunisian Nuclear Power program. The Tunisian Nuclear project team has been trained by GENIVAR nuclear division team on behalf of the IAEA.

ENAQ PROJECTS & SERVICES PROVIDED TO ENERGY POWER SECTORS:

- 2018: Perform Reliability and Safety analysis to define the optimal design and Security architecture automation of substations of the Hydro-Quebec Electricity Grid transportation.

- 2017: Perform Technical-Economic study & Design to implement a 50 MW PV power plant in Basra city Iraq. This study has been carried out on behalf the Client Ministry of Industry Iraq.

- 2016: Perform the Fire Safe Shutdown Analysis (FSSA) for Pickering and Darlington power plants

- 2016: Perform Technical-Economic study & Design to implement a 100 MW PV power plant in Almaty city Kazakhstan. This study has been carried out on behalf of Spanish ARESOL client.

- 2015: Perform Technical-Economic study & Design of WTE plant within Bosra-Iraq city for the treatment and valorization of 1500 MT per day of MSW. This study carried out on behalf of Bosra City Mayor to evaluate the economic benefit to implement WTE units in Bosra city to produce electricity through pyrolysis-gasification technology and fertilizer from organic components.

- 2010-2012: Environmental design Qualification of Equipment’s Safety Systems and refurbishment of existing power and industrial facilities (Gentilly 2, NRU, Waste treatment center)

- 2011-01: Perform Technical-Economic study for 200 MW Wind Farm Project in the Gulf of Suez for the African Development Bank.

- 2009-2011: Probabilistic Safety Assessment for Fire and flood to evaluate the risk induced for the operation of Gentilly-2 Power Plant,

- 2007-2008: Probabilistic Safety Assessment of the internal accident events to evaluate the risk induced for the operation of Gentilly-2 Power Plant.

- 2009- Derivation of Hazards and internal initiating event frequencies for Gentilly-2 power plant.

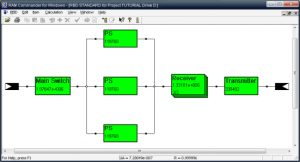

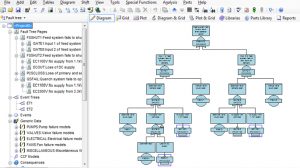

- 2008-2011- Development of fault tree models for various Special Safety Systems (SSS) and Related Safety Systems (SRS) using the CAFTA code suite for Gentilly-2 and Point Lepreau power stations.

- 2006-2008: Assessment of the Impact on Safety with Regard to Change in Outage Interval from 12 to 18 or 24 months at Gentilly-2 Nuclear Generating Station.

- 2000-2017: Design-assist analysis for modifications to existing power and industrial facilities (Gentilly-2, NRU, U2 Loop Test Facilities, Waste Treatment Center Facility at Chalk River Site, etc..) and during commissioning.

- Characterization of design specification of Equipment for nuclear Special Safety Systems and Related Safety Systems.

- Modelling the recirculating service water (RSW) of Gentilly-2 to improve Design. The modelling is intended to analyze the design changes carried in order to prevent the water hammer phenomena following a loss of class IV electric power.

- Validation of the BILTHERM Software used by G2 Fuel Management group to monitor the reactor bulk power in order to comply with the OP&P.

- Lead a team with several team members in designing single-pole-tripping-and-reclosing at the distribution level for Exelon & PEPCO’s Washington DC and Maryland region.

- Lead the design of a mission critical generation (~ 450 MW) shedding RAS using the latest IEC-61850 technology.

- Participated in the clients ARS (Alberta Reliability Standard) Compliance preparation work. Developed tools to review (check or change) load responsive zone reaches in the transmission lines’ distance protection and load responsive overcurrent elements in the power transformer protection.

- Interconnected power generation plants onto transmission level (138 – 500 kV) and distribution level (25 kV). Handled typical interconnection issues such as weak sourced protection, RAS, anti-islanding or planned islanding, signal interfacing and design coordination between different entities.

E|N|A|Q expertise using international Standards and Regulatroy guide documents to perform and align client’s projects as per the international quality and requirements:

- IEC 60812 (Analysis techniques for system reliability – Procedure for failure mode and effects analysis (FMEA);

- IEC 60863 (Reliability, Maintainability, and Availability Predictions);

- IEC 61025 (Fault Tree Analysis);

- NEI 00-01 (Guidance for Post Fire Safe Shutdown Circuit Analysis);

- IEC 61078 (Analysis techniques for dependability – Reliability block diagram method);

- IEC 61508 (Functional safety);

- IEC 61511 (Functional safety – Safety instrumented systems for the process industry sector);

- IEC 60076 Power Transformers;

- IEC 61580 Communication Protocols in Substation Automation;

- MIL-STD-785 (Reliability Program for Systems and Equipment, Development and Production);

- MIL-STD-217F (Reliability Prediction of Electronic Equipment N2/470B);

- NEI 07-12 Fire Probabilistic Risk Assessment (FPRA) Peer Review Process Guidelines;

- NEI 05-04, Process for Performing Internal Events PRA Peer Reviews Using the ASME/ANS PRA Standard;

- IEC 62443 Industrial communication networks – Network and system security;

- IEC 62455 Internet protocol (IP) and transport stream (TS) based service access;